Injection Systems Engineering

China Diesel Fuel Injector Suppliers and Diesel Fuel Injector Manufacturers

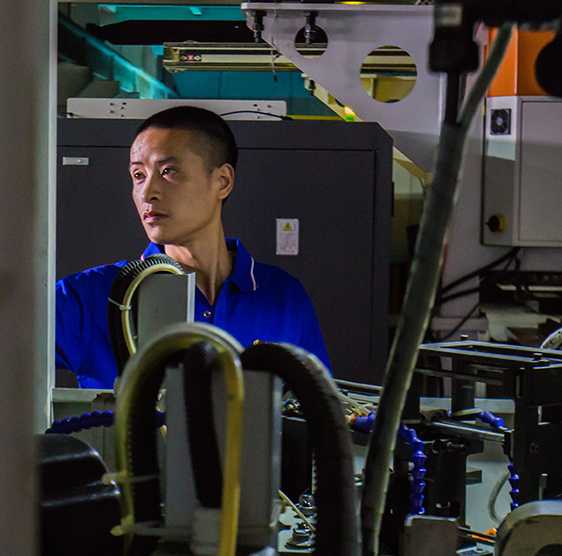

, DOKA has successfully passed the IATF16949:2016 automotive industry quality management certification and has been recognized as a "National High-Tech Enterprise" .-

0m2

R&D Base

-

0m2

Factory Area

-

0+

Own Property Rights

-

0+

R&D Team

-

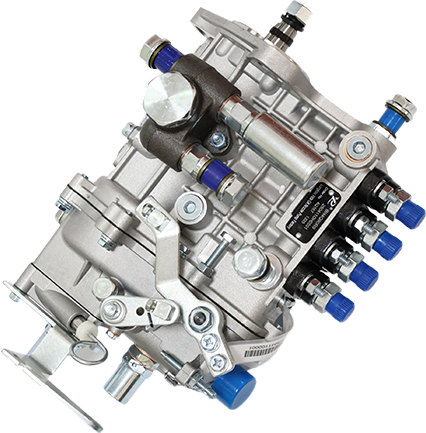

Bo-sch Series

Bo-sch Series -

Cater-pillar Series

Cater-pillar Series -

DEN-SO Series

DEN-SO Series -

Del-phi Series

Del-phi Series -

Yan-mar Series

Yan-mar Series -

Fuel Injector Parts

Fuel Injector Parts -

Precision Finished Productsview more

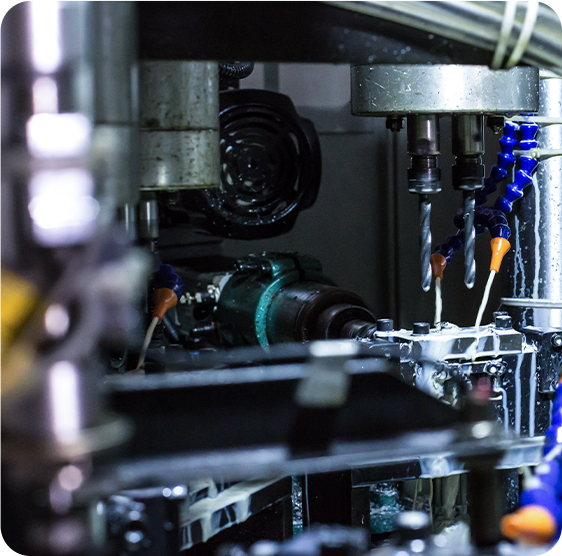

Precision Finished Productsview moreAs the core load-bearing unit of compaction machinery, the impact rammer housing must simultaneously fulfill three key functions: transmitting extreme impact loads, integrating hydraulic systems, and controlling thermal deformation. The primary challenges in its manufacturing process include: a multi-chamber composite structure, asymmetric stress distribution, and dynamic sealing requirements. The company operates 23 high-precision CNC machining centers, specializing in the custom production of precision-machined components to empower the engineering machinery industry.

operation, and dual-cylinder configurations—enhancing performance and environmental compliance.

-

Why Choose Us2,000 m² R&D Center

Why Choose Us2,000 m² R&D Center

25 Patents Securing Technological Leadership Flexible Manufacturing System

Flexible Manufacturing SystemWe have introduced a full suite of internationally advanced manufacturing equipment for fuel injection pumps and injectors, making us one of the few specialized enterprises in the industry capable of producing nozzles, plungers, and valves simultaneously. Our lean and agile manufacturing system enables us to rapidly adapt to market changes and deliver customer-tailored solutions.

-

Why Choose Us2,000 m² R&D Center

Why Choose Us2,000 m² R&D Center

25 Patents Securing Technological Leadership Dual-Track Product Strategy

Dual-Track Product StrategyWe offer a dual product lineup—high-precision premium models and cost-effective durable models—covering a wide range of categories with price points from CNY 100 to 1,000. This enables us to deliver custom-engineered solutions that precisely match specific customer requirements.

-

Why Choose Us2,000 m² R&D Center

Why Choose Us2,000 m² R&D Center

25 Patents Securing Technological Leadership Full-Process Digital Quality Control

Full-Process Digital Quality ControlOur cumulative product sales have exceeded 2 million units, with an annual installation volume of fuel injection systems reaching 1.2 million sets. We have consistently ranked among the top three in sales of core internal combustion engine components in China for three consecutive years (Source: China Internal Combustion Engine Industry Association), firmly establishing our position as an industry benchmark.

Core Engine Systems

Latest Enterprise and Industry News.

中文

中文 English

English русский

русский Español

Español