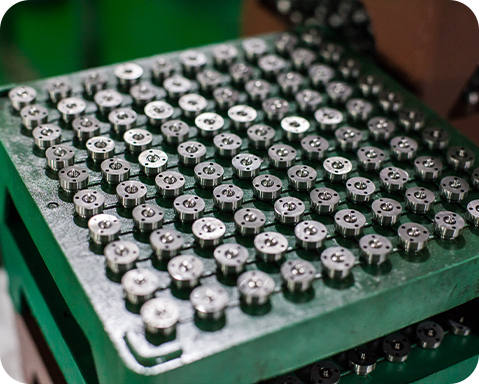

Innovation & Quality

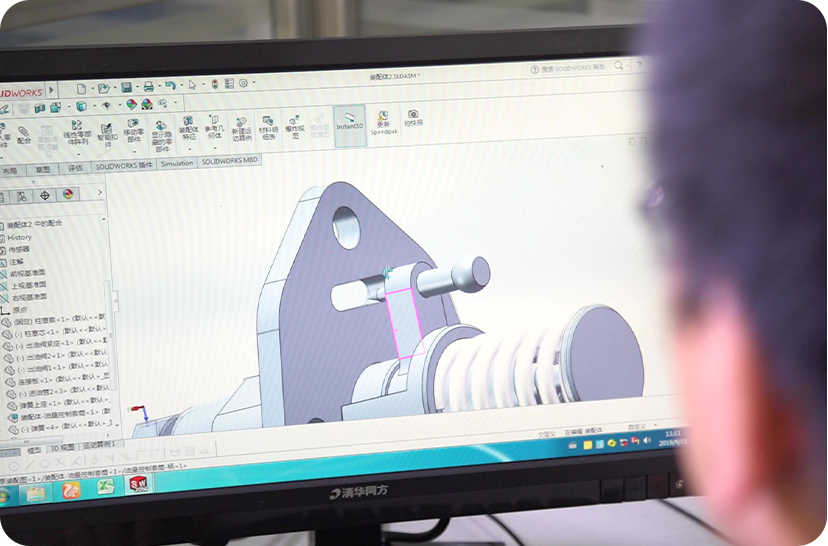

Pioneering Innovations in Fuel Injection Technology.

Provide professional product selection advice and technical consultation based on customer needs to ensure high compatibility between products and application scenarios.

Through digital systems, customers can understand the production progress of orders in real time to ensure timely project delivery.

Establish a rapid response mechanism to ensure that customer feedback issues can be resolved in the shortest possible time.

DOKA has established service networks in multiple countries and regions to ensure that global customers can receive timely and professional service support.